5 Things Found in Equipment Fluids

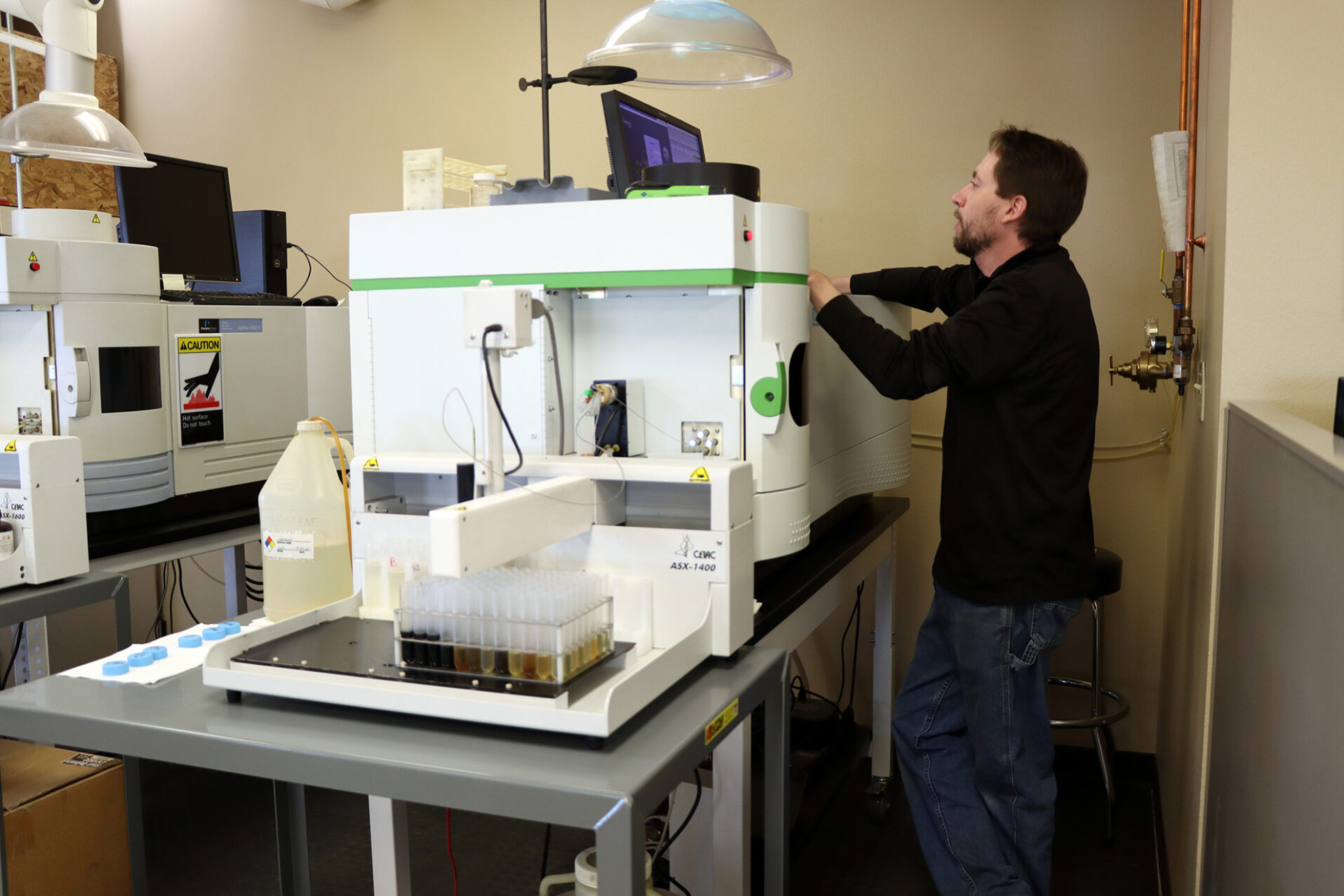

During S.O.S services analysis, multiple tests are performed on engine, hydraulic, and drive train oils—plus coolants, too. They can reveal a lot.

1. COMPONENT WEAR RATE

Why we do it:

Each oil-washed system has a particular concentration of wear metals produced during normal operation. By evaluating wear inside the lubricated compartment, we can see if rates are normal or not. For example, high levels of iron and chrome can stem from problems with your engine’s cylinder liners and/or piston rings.

What are we looking for?

- Wear metals — including iron, lead, copper, aluminum, and chrome

- Silicon — can indicate dirt entry, depending on local soil conditions

- Sodium — a potential indicator of water or coolant entry

2. OIL CONDITION

Why we do it:

Wear occurs when oil depletes its additives and begins to deteriorate. This can damage components in oil-washed compartments. It is important to know if the oil has reached the end of its useful life.

What are we looking for?

- Viscosity (how the oil flows) — too low and wear can occur; too high and oil won’t do its job

- Oxidation (oxygen molecules joining with lubricant molecules) — in diesel engines, oxidation can trigger sticking piston rings; in hydraulics, oxidized lubricants will increase pump wear and damage valves

- Sulfation (sulfur combining with water during diesel fuel combustion) — can corrode valves, cylinder liners, and more

- Nitration (generally a problem in natural gas engines) — may result in oil filter plugging, crankcase deposits, and other issues

3. OIL CONTAMINATION

Why we do it:

This robust analysis involving several tests can determine if anything harmful has entered the oil.

What are we looking for?

- Soot (from partially burned fuel) — can plug oil filters and cause engine wear

- Fuel — can come from the combustion process and cause low viscosity

- Water (such as from condensation, leaks, wet conditions) — can cause wear, rust, and sludge

- Coolant — can contaminate engine oil

4. OIL IDENTIFICATION

Why we do it:

The wrong fluid in the wrong compartment can affect performance and lube protection, or even severely damage major components. To tell if it’s the right fluid, it’s important to take an accurate sample with the right labeling.

What are we looking for?

- Viscosity — is it optimal for the geared compartment and your application?

- Additive chemistry — is the oil appropriate based on its unique chemical makeup?

5. COOLANT ANALYSIS

Why we do it:

Today’s heavy-duty engines produce a lot of power from a small package, and cooling systems have to do more with less. Also, customers may be extending drain intervals or recycling to reduce disposal costs.

What are we looking for?

- Coolant type — with so many on the market, they all have different chemistries

- Boil & freeze protection — to monitor fluid’s ability to provide adequate protection

- Condition — to test health for pH, conductivity, nitrite, solids, odor, color, and appearance

- Contamination — has anything harmful entered?